WEIGH IN MOTION |

Certification for WIM

Different situations require different scales and sensors for ensuring

over-loaded vehicles are prevented from damaging public roads. OIML

certification ensures the various systems are up to the required standard

Words | Jon Arnold, Intercomp, USA

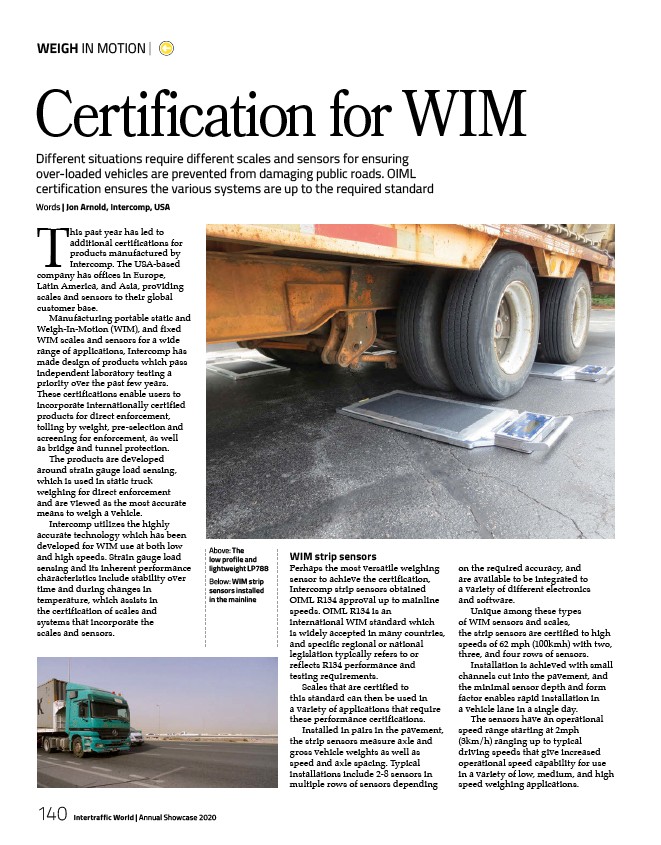

Above: The

low profile and

lightweight LP788

Below: WIM strip

sensors installed

in the mainline

This past year has led to

additional certifications for

products manufactured by

Intercomp. The USA-based

company has offices in Europe,

Latin America, and Asia, providing

scales and sensors to their global

customer base.

Manufacturing portable static and

Weigh-In-Motion (WIM), and fixed

WIM scales and sensors for a wide

range of applications, Intercomp has

made design of products which pass

independent laboratory testing a

priority over the past few years.

These certifications enable users to

incorporate internationally certified

products for direct enforcement,

tolling by weight, pre-selection and

screening for enforcement, as well

as bridge and tunnel protection.

The products are developed

around strain gauge load sensing,

which is used in static truck

weighing for direct enforcement

and are viewed as the most accurate

means to weigh a vehicle.

Intercomp utilizes the highly

accurate technology which has been

developed for WIM use at both low

and high speeds. Strain gauge load

sensing and its inherent performance

characteristics include stability over

time and during changes in

temperature, which assists in

the certification of scales and

systems that incorporate the

scales and sensors.

140 Intertraffic World | Annual Showcase 2020

WIM strip sensors

Perhaps the most versatile weighing

sensor to achieve the certification,

Intercomp strip sensors obtained

OIML R134 approval up to mainline

speeds. OIML R134 is an

international WIM standard which

is widely accepted in many countries,

and specific regional or national

legislation typically refers to or

reflects R134 performance and

testing requirements.

Scales that are certified to

this standard can then be used in

a variety of applications that require

these performance certifications.

Installed in pairs in the pavement,

the strip sensors measure axle and

gross vehicle weights as well as

speed and axle spacing. Typical

installations include 2-8 sensors in

multiple rows of sensors depending

on the required accuracy, and

are available to be integrated to

a variety of different electronics

and software.

Unique among these types

of WIM sensors and scales,

the strip sensors are certified to high

speeds of 62 mph (100kmh) with two,

three, and four rows of sensors.

Installation is achieved with small

channels cut into the pavement, and

the minimal sensor depth and form

factor enables rapid installation in

a vehicle lane in a single day.

The sensors have an operational

speed range starting at 2mph

(3km/h) ranging up to typical

driving speeds that give increased

operational speed capability for use

in a variety of low, medium, and high

speed weighing applications.